measurements of the bracelet - bigger dimensions

measurements of the bracelet - smaller dimensions

This part is for the LED to hold in place inside the object. I created it in Autodesk Inventor and then exported it to as a .dwg file to put it back into Rhino and keep transforming it. First I just made a basic rectangle and filleted the top edges. Then I put a 5mm hole into it and filleted the edge as well.

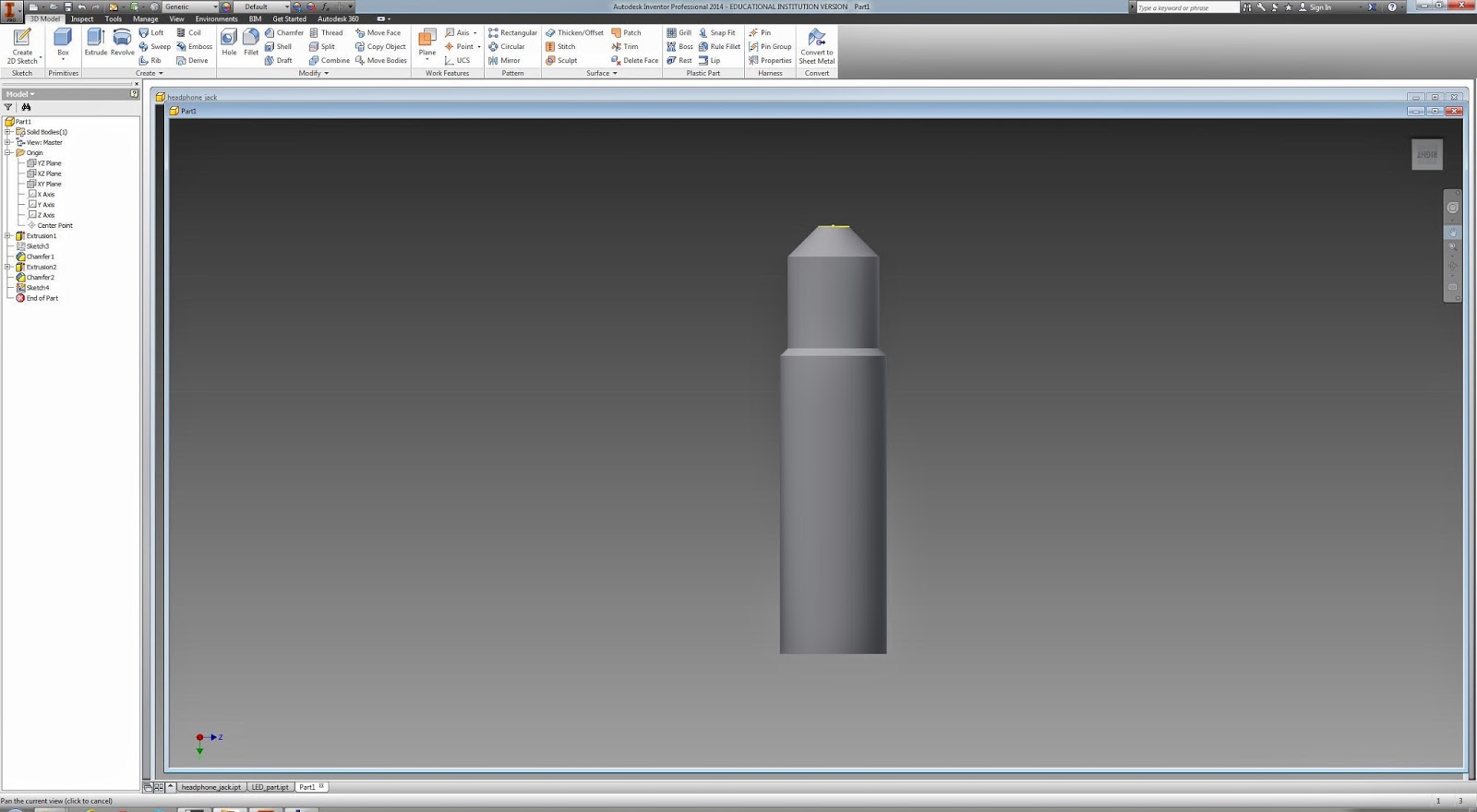

This is a basic headphone jack, I started it in Autodesk Inventor and finished it in Rhino. So I started with basic circles and extrusions to get a basic shape. These then I filleted at the edges and joined them. Inventor is still very unfamiliar to me so in the end couldn't go much further than this. Therefore exported it again as a .dwg file.

Here I imported the file from Inventor and with boolean difference made the grooves.

To make it more visible that the inside bit can be taking out, I added the arrow (triangle) with the two lines underneath which one can see anywhere where a battery is being used, ie. a tv remote.

The 3 shapes I extruded and rotated them to the angle of the curve. Then boolean union one and the other I used boolean difference. The engraved one is most commonly used. I also made the things that hold this all in place in the object, longer as in width and height. Otherwise it would be easier to break off.

The loop for the LED in Rhino. The first thing I did was measure it as last time I used Inventor and the measurements they were always way too big to be printed.

I copied and pasted to make a total of 6. These then rotate to good positions and along the curve. With boolean union I joined them together.

The rectangles at the edges are for the 'lid' so it doesn't fall in as it did before.

Making a cylinder and boolean difference to do the insert for the headphone plug. First I had to Boolean union the cylinder to the object and then do the whole difference thing. It had to be done like this because if I did the boolean difference first and then union it would cut of the end bit of the headphone plug shape.

The switch. The switch is so basic as I just extruded one of the surfaces of the 'path blocks' and sized it down so it floats in there at the moment. Then I'm going to connect it to an actual switch bought from the store jaycar.

front view of all the inside stuff.

Outline shape of the side face with a representation of the speaker output. this will be laser cut either with plywood or acrylic and attached to the side.

No comments:

Post a Comment